Simplifying Waveform Analysis

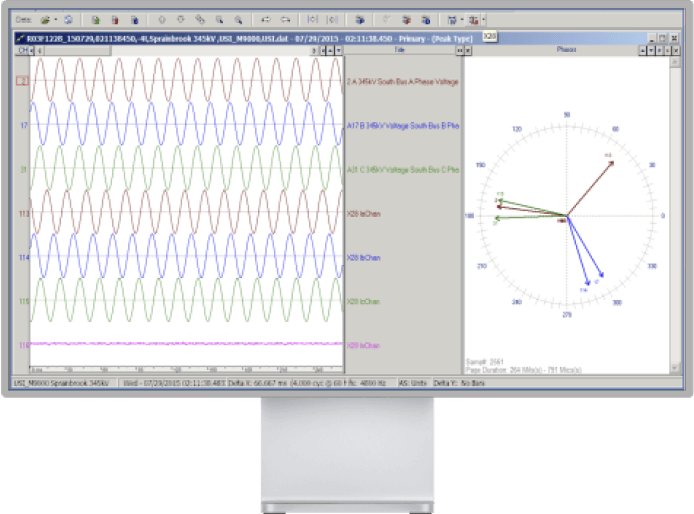

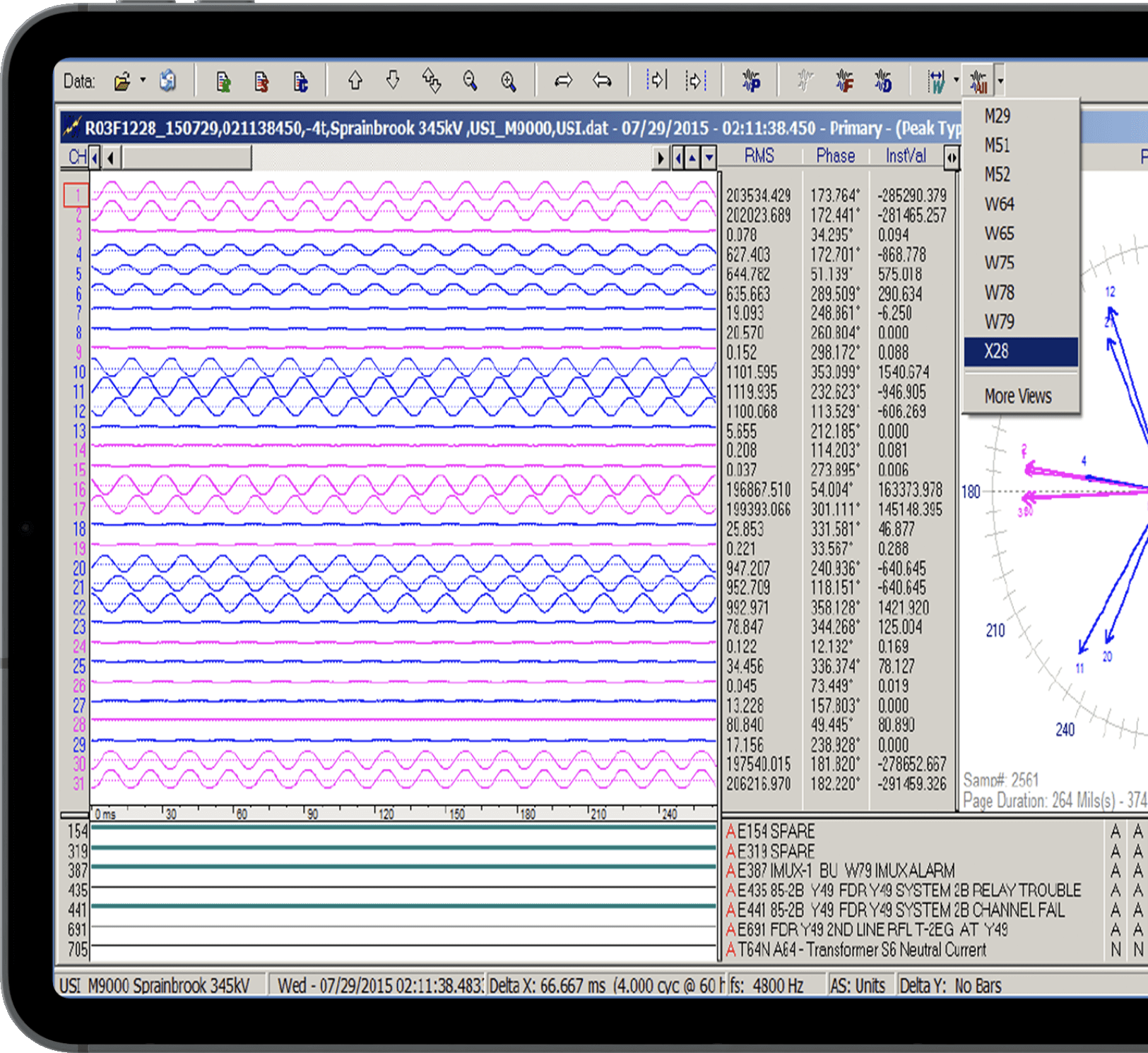

Along with industry partner Softstuf, a software development company, SynchroGrid provides the best fault oscillographic software on the market: Wavewin. In operation across North America and Europe by major utilities and manufacturers, Wavewin offers our clients more than 25 years of software development expertise, with no foreseeable limit to its potential growth.

Request a Quote

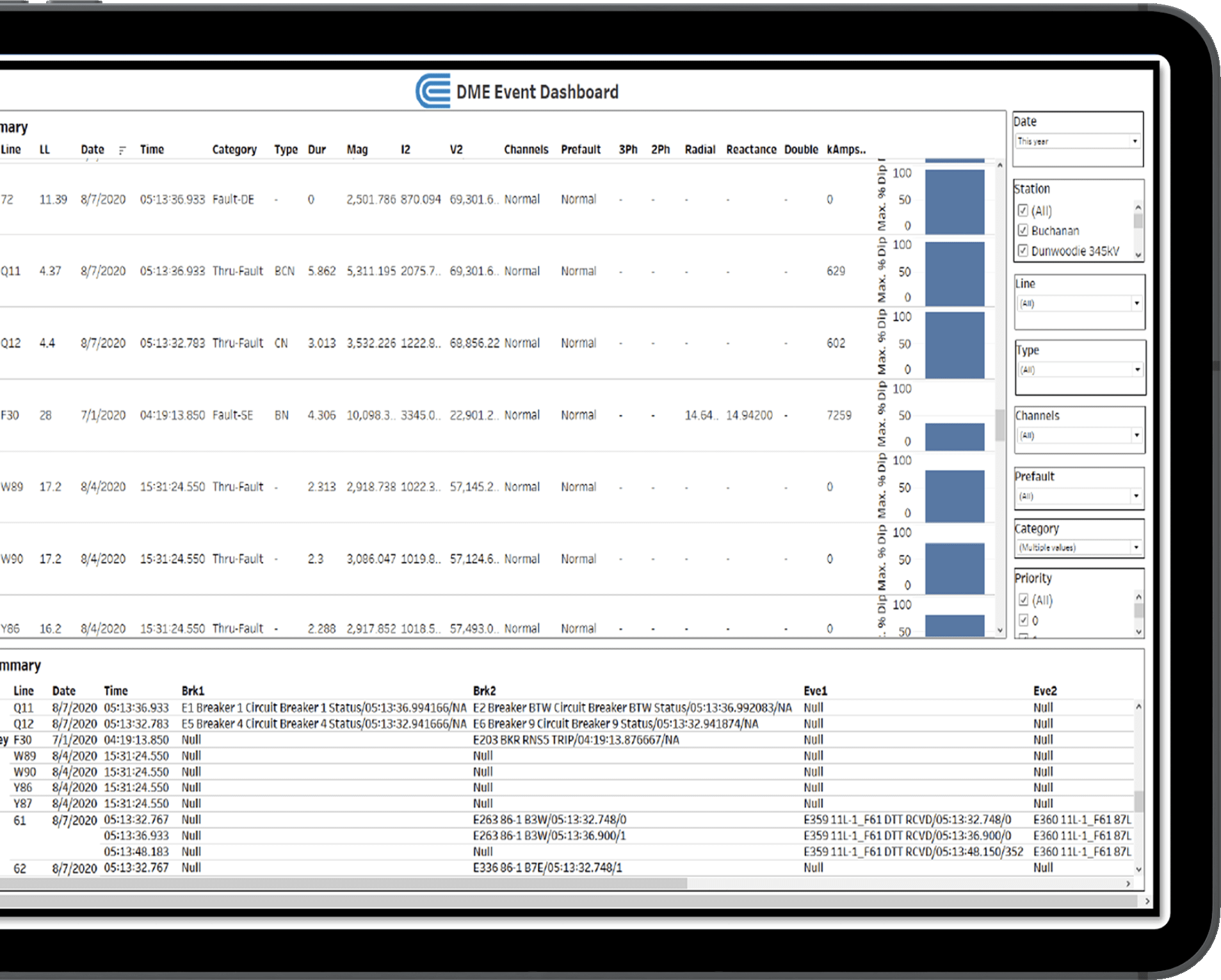

Through Wavewin, SynchroGrid offers clients the premier fault oscillographic software on the market for the analysis of disturbance monitoring equipment (DME) data — no other program comes close in performance. Wavewin software allows users to conduct remote retrieval of oscillography and sequence-of-event (SOE) data from a variety of substation devices.

Learn more about Wavewin and how it can boost your performance today by visiting SoftStuf’s website!

Our Other Software